High volume CNC machining has become a critical component for manufacturers aiming to deliver large quantities of precision parts efficiently and cost-effectively. Optimizing workflow in such demanding environments is essential to maintain productivity, minimize downtime, and ensure consistent quality. This article explores key strategies and best practices for streamlining operations, reducing bottlenecks, and maximizing the overall efficiency of high volume CNC machining.

Streamlining Setup and Changeover Processes

One of the biggest challenges in high volume CNC machining is minimizing setup and changeover times between production runs. Reducing these intervals can significantly increase machine utilization and throughput. A lean manufacturing approach that incorporates standardized setups and quick-change tooling can be highly effective. Using modular fixturing systems allows operators to rapidly swap workpieces without compromising alignment, which accelerates the transition from one batch to another.

Furthermore, investing in advanced CNC control software that supports automated tool offsets and pre-programmed setups can save valuable time. Many modern CNC machines allow operators to preload tooling and programs while the machine is still running a job, thereby preparing for the next run in parallel. When setups are standardized and changeovers are swift, it reduces idle time and enables a smoother flow in high volume CNC machining operations.

Implementing Real-Time Monitoring and Data Analytics

In high volume CNC machining, real-time monitoring of machines and workflows provides crucial insights that help prevent downtime and maintain quality standards. Using sensors and IoT-enabled devices, manufacturers can track tool wear, machine vibrations, temperature, and other parameters that impact machining performance. Early detection of anomalies allows for timely interventions before a problem escalates into costly downtime or scrap parts.

Data analytics platforms can also analyze production trends and identify inefficiencies within the workflow. For example, by reviewing cycle times, tool change frequency, and material usage, operations managers can pinpoint bottlenecks or underperforming equipment. Leveraging this data supports continuous improvement efforts, enabling informed decision-making and more precise scheduling to optimize overall throughput in high volume CNC machining.

Enhancing Tool Management and Maintenance Strategies

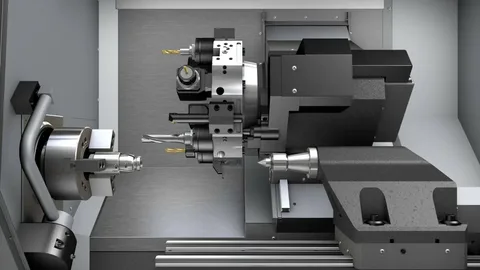

Effective tool management is vital for sustaining productivity in high volume CNC machining operations. Tools must be tracked meticulously to ensure optimal usage and timely replacements. Implementing a tool management system that catalogs tool types, life expectancy, and usage history reduces unexpected failures and improves cost control. This approach also prevents unnecessary tool changes and extends tool life by enabling predictive maintenance.

Routine preventive maintenance of CNC machines and tooling equipment is equally important to avoid unexpected breakdowns. Scheduled inspections, cleaning, and calibration ensure that machines operate within specifications and maintain tight tolerances. Additionally, integrating automated tool setters and calibration devices helps maintain consistent accuracy and reduces operator dependency, thereby improving workflow stability in high volume CNC machining environments.

Optimizing Material Handling and Inventory Control

Material flow plays a crucial role in maintaining efficient workflow in high volume CNC machining. Delays caused by poor material handling or stock shortages can disrupt production schedules and increase lead times. To avoid these pitfalls, manufacturers should design streamlined material handling processes that minimize movement and reduce handling steps. Automated conveyors, robotic arms, and just-in-time (JIT) inventory practices can accelerate material delivery to machines.

Inventory control systems integrated with production scheduling software can ensure that raw materials and consumables are replenished before shortages occur. Accurate inventory tracking reduces the risk of overstocking or stockouts, which can both impact costs and workflow continuity. By synchronizing material supply with production demand, high volume CNC machining operations can maintain a steady flow of inputs, ensuring uninterrupted machining cycles and meeting customer delivery deadlines.

Fostering Skilled Workforce and Continuous Training

Even the most advanced machinery and optimized processes require skilled operators and technicians to achieve peak performance in high volume CNC machining. Investing in workforce training ensures that employees understand machine programming, operation, troubleshooting, and quality control procedures. Skilled operators can quickly adapt to changing production demands and identify potential issues before they escalate.

Continuous education also promotes a culture of continuous improvement and innovation. Providing employees with training on the latest CNC technologies, software updates, and lean manufacturing principles empowers them to contribute ideas for workflow enhancements. Furthermore, cross-training operators on multiple machines and processes adds flexibility to production scheduling, making the entire high volume CNC machining operation more resilient to fluctuations in demand or staffing.

Conclusion

Optimizing workflow in high volume CNC machining operations requires a comprehensive approach that encompasses efficient setup, real-time monitoring, proactive tool management, streamlined material handling, and a skilled workforce. By focusing on these critical areas, manufacturers can increase machine utilization, reduce downtime, and consistently produce high-quality parts at scale. As the demands of mass production continue to grow, companies that invest in workflow optimization will gain a significant competitive edge in the fast-paced CNC machining industry.