A Shower Drainage System Factory plays a pivotal role in modern bathroom design and functionality. These specialized facilities combine engineering precision with material science to create solutions that effectively manage water flow while complementing contemporary bathroom aesthetics.

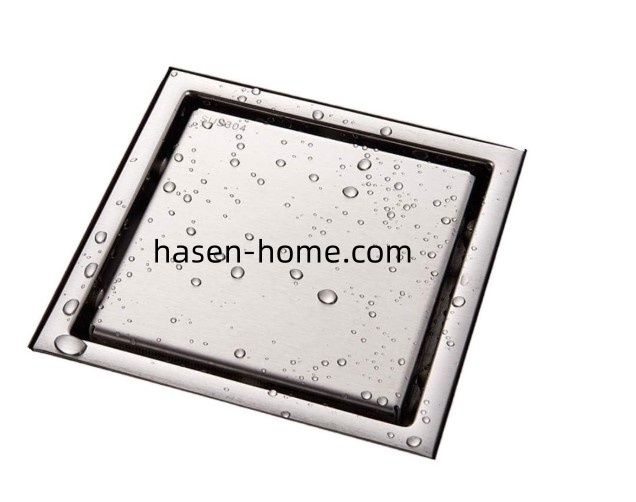

The manufacturing process begins with careful material selection. High-grade stainless steel and durable polymers undergo rigorous testing for corrosion resistance and structural integrity. These materials must withstand constant water exposure while maintaining their appearance over years of use.

Engineering teams focus on optimizing drainage efficiency through calculated slope designs and strategically placed channels. The grid patterns are carefully designed to prevent hair and debris accumulation while allowing rapid water flow. These technical considerations directly impact the system's long-term performance and maintenance requirements.

Installation processes receive equal attention in the production phase. Modern systems incorporate user-friendly features that simplify the installation process while ensuring proper alignment and sealing. This attention to detail helps prevent common issues like leaks or improper water flow direction.

Quality assurance protocols form the backbone of the manufacturing operation. Each completed unit undergoes multiple inspections, including water flow tests and stress evaluations. These procedures verify that every component meets established performance benchmarks before leaving the facility.

The finished products combine functionality with design flexibility. Contemporary options include various finishes and styles to complement different bathroom décors, from minimalist modern to traditional designs. This versatility allows homeowners and designers to select systems that match their specific aesthetic preferences.

For those interested in exploring these solutions further, additional information is available at https://www.hasen-home.com/