In the modern manufacturing landscape, efficiency and intelligence are the key drivers behind successful production lines. Among various processes, carton packaging stands out as a crucial stage that significantly impacts the final product presentation and logistics. The advent of SANTUO intelligent carton packaging lines has revolutionized this process, ensuring high throughput, precision, and adaptability.

Overview of Intelligent Carton Packaging Line

An intelligent carton packaging line integrates advanced robotics, automation, and sensor technologies to streamline the packaging process. It operates seamlessly from the initial stages of box conveying to the final sealing of the carton, ensuring consistency and quality at every step. Below is a detailed breakdown of how this sophisticated system functions.

Box Conveying: The Initial Step

Box Conveying marks the beginning of the intelligent packaging journey. Automated conveyors are equipped with sensors that detect the presence and orientation of incoming boxes. These conveyors ensure smooth and timed transfer of boxes to the next station, laying the foundation for subsequent operations.

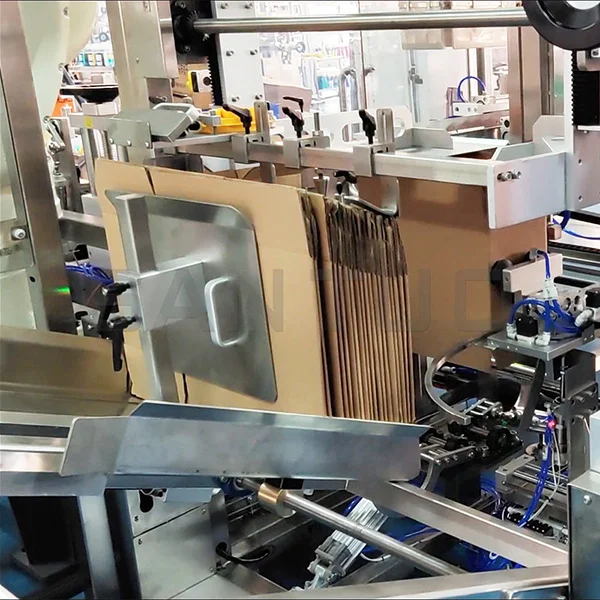

Quantitatively Collect Box Columns

Once conveyed, the boxes are organized into columns through a Quantitative Collection Station. Here, mechanical arms or pneumatic systems precisely stack boxes into columns, ensuring a consistent feed rate for the subsequent grouping station. This step is crucial for maintaining the flow and synchronization of the entire packaging line.

Push the Box into the Grouping Station

Boxes are then Pushed into the Grouping Station, where they are prepared for further processing. This station aligns boxes in preparation for shaping and packing, ensuring they are in the correct orientation for the next steps. Sensors play a vital role here, constantly monitoring and adjusting box positions to maintain accuracy.

Suck Box to Shape It

Next, a vacuum system Sucks the Box to Shape It. This step involves using suction cups to lift and slightly compress the box, helping it achieve its intended shape and form. Vacuum technology ensures gentle handling, preventing damage to the box material and maintaining its structural integrity.

The Box Enters the Packing Station to be Erected

Once shaped, the box Enters the Packing Station where it is fully erected. This is often achieved through mechanical folding mechanisms that gently press the box into its final, three-dimensional form. Erecting the box correctly is critical for smooth insertion of products and partitioning.

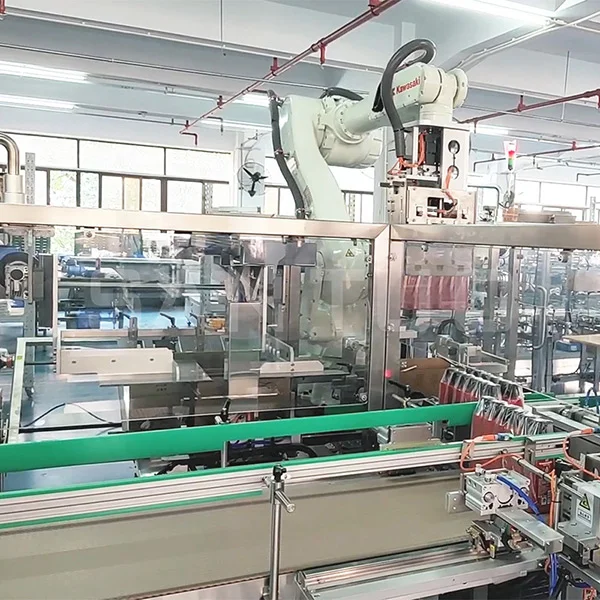

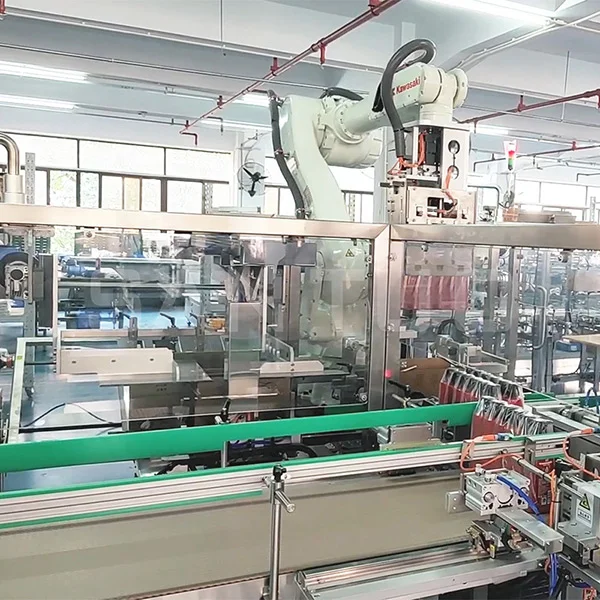

The Robot Picks Up the Paper Partition and Places It at the Bottom of the Box

At this stage, a Robot Picks Up the Paper Partition and places it at the bottom of the erected box. Precision robotics, guided by advanced vision systems, ensure accurate placement of partitions, which are vital for separating different products within the same box.

The Robot Picks Up the Box and Performs the Packing Operation

With the partition in place, the Robot Picks Up the Box and moves it to the packing area. Here, the robot carefully inserts the products into the box, adhering to predefined packing patterns. This step leverages the robot's dexterity and precision to handle a variety of product shapes and sizes.

The Robot Picks Up and Places the Certificate of Conformity

After packing, a Robot Picks Up and Places the Certificate of Conformity inside the box. This document, crucial for quality assurance and traceability, is placed in a designated spot using the robot's vision-guided systems for accuracy.

The Robot Picks Up the Partition and Places It on Top of the Box

To complete the internal arrangement, the Robot Picks Up the Partition again and places it on top of the packed products. This additional layer of partitioning ensures products remain secure and organized during transportation.

The Robot Closes the Box

Finally, the Robot Closes the Box. Utilizing sophisticated gripping mechanisms, the robot folds and seals the box flaps, often with the aid of adhesive applicators. This final step not only secures the contents but also presents a professional and tamper-evident package ready for shipping.

Conclusion

The intelligent carton packaging line represents a pinnacle of modern manufacturing innovation. By automating and intelligently managing each step from box conveying to final sealing, it enhances efficiency, reduces errors, and ensures product quality. As technology continues to evolve, these lines will only become more sophisticated, further driving advancements in the packaging industry. The seamless integration of robotics, sensors, and automation technologies underscores the potential for even greater efficiency and intelligence in future packaging solutions.