When working with high volumes of labels—especially in industries like pharmaceuticals, food, cosmetics, or industrial goods—label handling can quickly become a bottleneck if not managed properly. That’s where a Label Rewinder becomes an essential part of the process.

But what exactly does a label rewinder do? And how can it support better label management and inspection?

Understanding the Role of a Label Rewinder

At its core, a label rewinder is a machine that transfers labels from one roll to another. It may sound simple, but this process allows for several critical tasks to be carried out efficiently, including:

· Label counting

· Code printing or marking

· Barcode reading

· Label direction adjustment

· Visual inspection for label quality

Depending on the production needs, many of these features can be flexibly configured.

Why Use a Label Rewinder?

Label rewinders are not just about winding and unwinding. For companies that need to manage large rolls of labels or film, especially when quality and traceability are critical, rewinders provide a centralized way to prepare, check, and enhance labels before they reach the final packaging stage.

For example:

· In the pharmaceutical industry, a label rewinder helps ensure serialized codes are correctly printed and readable.

· In the printing industry, it's used for visual quality checks and defect marking.

· In food and beverage packaging, it's often used for film coding or label orientation correction.

Key Features to Look For

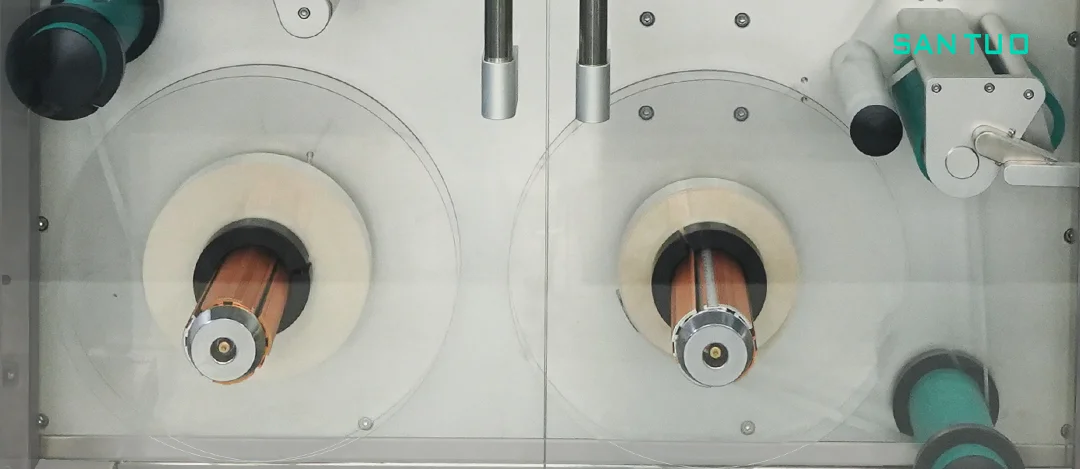

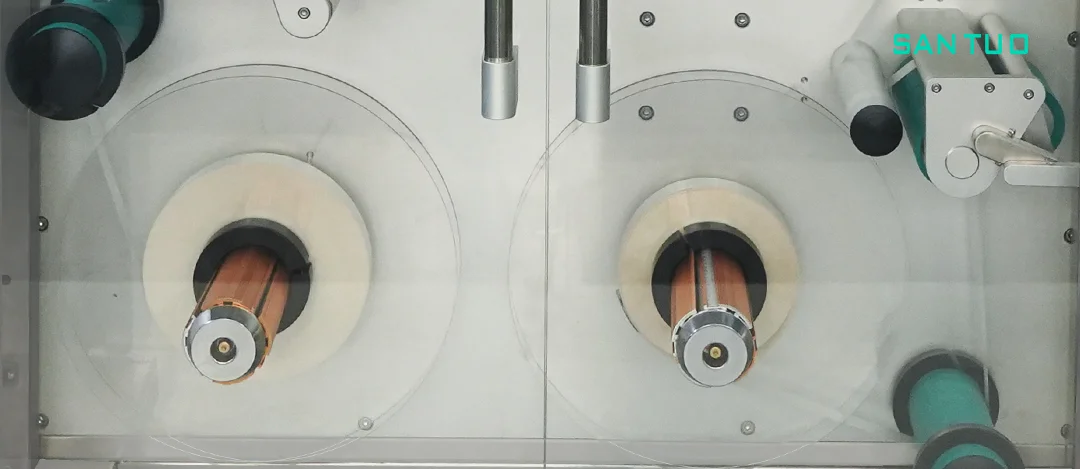

When selecting a label rewinder, flexibility and precision are key. A well-designed rewinder, such as the vertical model offered by SanTuo, can support multiple functions while maintaining ease of use. Some useful features include:

· Pneumatic tension shafts for easy loading and unloading

· Web guiding systems for neat and aligned rewinding

· Touchscreen interface for user-friendly operation and label count display

· Reserved mounting space for laser markers, inkjet printers, or vision systems

· Optional visual inspection modules to identify and flag defects automatically

These features make the rewinder more than just a roll-handling device—it becomes part of your inspection and quality assurance process.

Is a Label Rewinder Right for Your Operation?

If your production involves high label throughput, precise marking requirements, or strict visual quality control, integrating a label rewinder into your workflow can save both time and manual labor. It's especially helpful for facilities that need to:

· Prepare labels for later application

· Verify label printing results

· Switch label winding direction

· Ensure label integrity before shipping

Final Thoughts

A label rewinder is a small but powerful tool that can make a big difference in label handling, coding, and inspection. Whether you're a packaging engineer, quality manager, or production supervisor, it's worth considering how this equipment can improve your process.