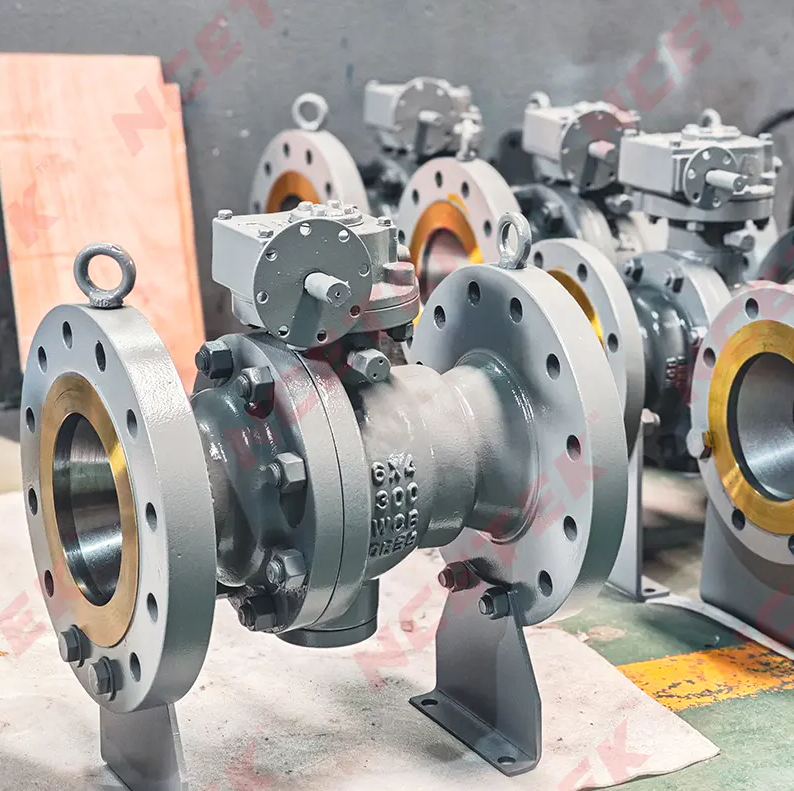

Power plants can’t afford unplanned shutdowns. A Cast Steel Trunnion Mounted Ball Valve is engineered for exactly that challenge. Because the ball is anchored at top and bottom, it stays perfectly centered when steam or super-heated water rushes through the line; seats stay in contact without being hammered, so sealing integrity remains high cycle after cycle. The quarter-turn action gives operators instant control over feed-water or steam isolation, allowing turbines to come offline or restart quickly without risking water hammer or thermal shock. Cast steel body absorbs the repeated expansion and contraction that happens when a unit ramps from idle to full load, keeping the valve body free of the micro-cracks that invite leaks. Fire-safe graphite seals and an anti-blowout stem add an extra safeguard if a nearby line ruptures. Together these features translate into fewer spares, less overtime, and predictable maintenance windows—critical advantages when every megawatt counts and grid regulators demand 99 % uptime.

Search

Categories

- Politics

- Home

- Wellness

- Theater

- Sports

- Shopping

- Religion

- Party

- Other

- Networking

- Music

- Literature

- Art

- Health

- Gardening

- Games

- Food

- Fitness

- Film

- Drinks

- Dance

- Crafts

- Causes

Read More

Market Dynamics and Strategic Insights: Navigating the Competitive Terrain of Microbiome Diagnostics Market

In its latest publication, Polaris Market Research presents an in-depth analysis of...

Why Mplussoft Is Becoming Pune’s Go-To Mobile App Development Company in 2025

In a city bursting with tech talent, standing out is no small feat. But Mplussoft, a Mobile App...

Computer Assisted Surgical (CAS) Systems Market Size, Share, Demand, Rising Trends, Growth and Competitors Analysis

Executive Summary Computer Assisted Surgical (CAS) Systems Market :

Data Bridge...

Composites Business Outlook: Trends and Landscape Forecast 2025 - 2032

Key Drivers Impacting Executive Summary Composites Market Size and Share

The composites...

How to Choose the Perfect Medical WordPress Theme for Your Website

Creating a professional and user-friendly website for your medical practice is essential in...