In the realm of industrial filtration, the choice of filter media is crucial for ensuring the efficiency and effectiveness of various processes. Among the myriad options available, carbon fiber filter elements have gained prominence due to their unique properties and advantages. This article delves into the role of carbon fiber filter elements in industrial filtration systems, highlighting their construction, benefits, applications, and comparisons with other filtration technologies.

What Are Carbon Fiber Filter Elements?

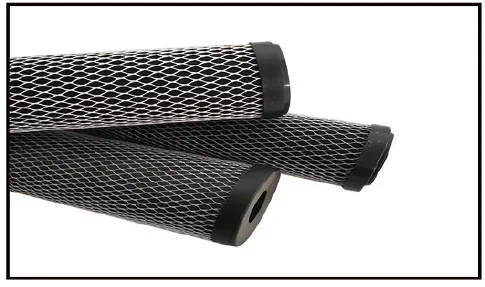

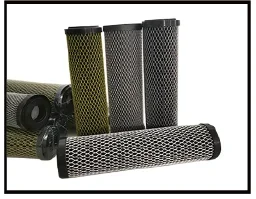

Composition and Structure

Carbon fiber filter elements are made from carbon fibers that are processed to create a network of fine filaments. These fibers exhibit a high surface area and porosity, which significantly enhances their adsorption capabilities. The structure allows for effective filtration of particulates and contaminants from liquids and gases, making them suitable for various industrial applications.

Types of Carbon Fiber Filters

Activated Carbon Fiber (ACF): This type is treated to increase its surface area and enhance its adsorption properties. ACF filters are particularly effective in removing organic compounds, odors, and chlorine from water.

Carbon Impregnated Filters: These filters combine carbon fibers with other materials, such as cellulose or polypropylene, to improve strength and dirt-holding capacity while maintaining high filtration efficiency.

Advantages of Carbon Fiber Filter Elements

1. High Adsorption Capacity

One of the most significant advantages of carbon fiber filters is their high adsorption capacity. The large surface area provided by the fine filaments allows these filters to capture a wide range of contaminants effectively. For instance, activated carbon fiber filters can adsorb more than three times the amount of chlorine and bad odors compared to standard carbon block filters.

2. Enhanced Filtration Efficiency

Carbon fiber filters provide depth filtration, meaning they can capture particles throughout the entire thickness of the filter material rather than just on the surface. This characteristic leads to longer service life and reduced frequency of replacement, ultimately lowering maintenance costs.

3. Chemical Resistance

Carbon fibers exhibit excellent resistance to a variety of chemicals, making them suitable for use in harsh industrial environments. They can withstand exposure to acids, bases, and solvents without degrading, ensuring consistent performance over time.

4. Lightweight and Flexible

The lightweight nature of carbon fiber allows for easy installation and handling. Additionally, their flexibility enables them to be used in various configurations and shapes, accommodating different filtration system designs.

Applications of Carbon Fiber Filter Elements

1. Water Treatment

Carbon fiber filters are extensively used in water purification systems due to their ability to remove chlorine, organic compounds, and unpleasant odors from drinking water. Their high flow rates make them ideal for both residential and industrial water treatment applications.

2. Air Filtration

In air filtration systems, carbon fiber elements are employed to capture volatile organic compounds (VOCs), smoke, and odors from industrial processes. Their chemical resistance allows them to function effectively in environments where traditional filters might fail.

3. Chemical Processing

In chemical manufacturing, carbon fiber filters play a critical role in maintaining product purity by removing contaminants from process streams. They are particularly useful in applications involving solvents or corrosive materials where traditional filter media may degrade.

4. Food and Beverage Industry

The food industry utilizes carbon fiber filters for decolorization and deodorization processes in liquids such as juices or spirits. Their ability to remove impurities without altering the flavor profile makes them an essential component in food processing.

Comparison with Other Filtration Technologies

To better understand the role of carbon fiber filter elements in industrial filtration systems, it is essential to compare them with other common filtration technologies.

1. Traditional Activated Carbon Filters

While traditional activated carbon filters are effective at removing impurities through adsorption, they generally have a lower capacity compared to carbon fiber filters due to their bulkier structure. Carbon fiber filters provide faster adsorption rates and higher efficiency due to their larger surface area.

2. Membrane Filters

Membrane filtration technologies offer precise particle size removal but may not be as effective at adsorbing dissolved contaminants or gases as carbon fiber filters. In many applications requiring both particulate removal and adsorption capabilities, a combination of membrane and carbon fiber filters can be employed for optimal results

3. Depth Filters

Depth filters utilize various materials (like cellulose or polypropylene) to trap particles throughout their thickness. While they can handle high dirt loads effectively, they may not match the adsorption capabilities of carbon fiber filters when it comes to removing specific contaminants like VOCs or odors.

Conclusion

Carbon fiber filter elements play a vital role in industrial filtration systems by providing efficient adsorption capabilities coupled with excellent chemical resistance and durability. Their unique properties make them suitable for a wide range of applications across various industries including water treatment, air purification, chemical processing, and food production.

Carbon Fiber Filter Elements: A Solution for Clean and Safe Drinking Water