Model-Based Enterprise: Improving Collaboration Across the Supply Chain

https://www.marketdigits.com/model-based-enterprise-market

Model-Based Undertaking: Driving Effectiveness and Advancement in Assembling

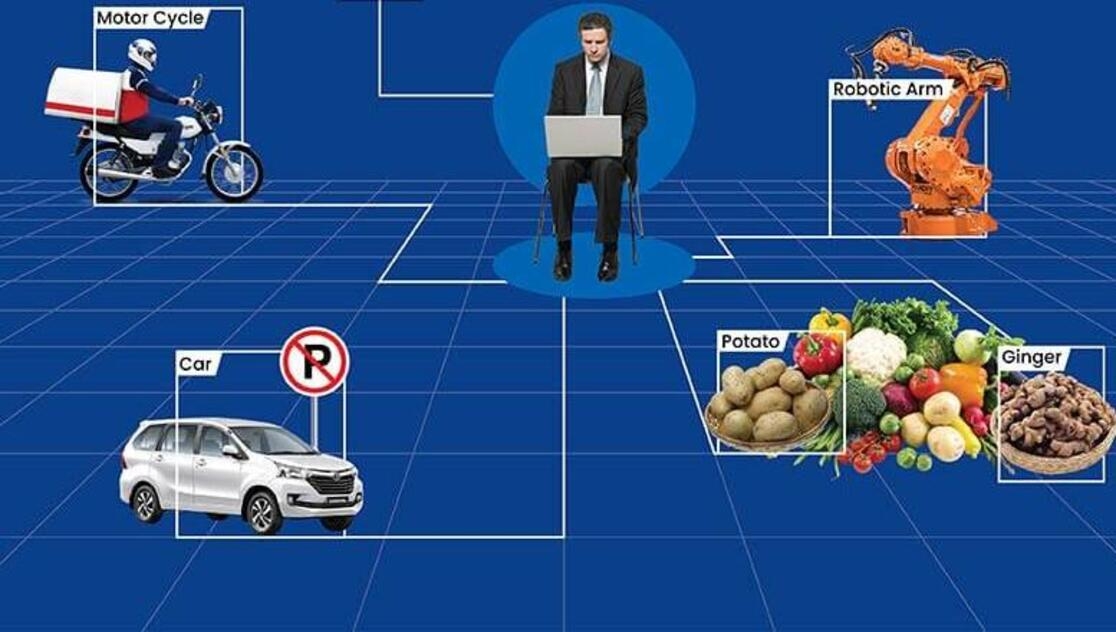

The Model-Based Enterprise (MBE) is a ground breaking methodology in present day fabricating that use computerized models to improve item improvement, creation, and lifecycle the executives. By utilizing far reaching computerized portrayals, or models, all through the whole venture, MBE empowers further developed cooperation, smoothed out cycles, and information driven navigation.

What is Model-Based Enterprise?

A Model-Based Enterprise is an association where the legitimate wellspring of data for movements of every sort, from plan to assembling to quality confirmation, is a computerized model. This model, frequently made in PC supported plan (computer aided design) programming, contains itemized data about the item, including its calculation, materials, resistances, and execution determinations.

MBE is a characteristic movement from the Model-Based Definition (MBD) approach, which centres around inserting item and assembling information straightforwardly inside 3D models. MBE makes this a stride further by coordinating these models across the whole endeavour, guaranteeing that plan, assembling, quality, and different groups are working from a similar wellspring of data.

Key Advantages of a Model-Based Enterprise

Further developed Coordinated effort: In a Model-Based Enterprise, all partners access a solitary, shared computerized model that contains forward-thinking and exact data.

Improved Effectiveness: By supplanting paper-based processes with computerized work processes, MBE kills mistakes and adjust. For instance, fabricating groups can straightforwardly utilize the advanced model to program CNC machines or 3D printers, guaranteeing that the item is constructed definitively to the plan details. This diminishes the probability of creation blunders and abbreviates lead times, eventually prompting higher efficiency.

Better Quality Control: MBE considers more thorough quality control processes by empowering the mix of continuous information from assembling and review processes into the advanced model. This implies that any deviations from the plan particulars can be immediately recognized and amended, further developing item quality and diminishing waste.

Cost Reserve funds: The smoothed out processes and decreased blunders that accompany MBE bring about massive expense investment funds. Organizations can decrease material waste, limit adjust, and abbreviate creation cycles.

Support for Development: By using advanced models, MBE makes it more straightforward to try different things with new plans, materials, and creation techniques. Specialists can mimic various situations and advance plans for all intents and purposes prior to focusing on actual models, diminishing the time and cost related with item improvement.

Challenges in Taking on Model-Based Venture

Notwithstanding its various benefits, carrying out a Model-Based Enterprise accompanies difficulties. One of the most critical is the underlying interest in innovation and preparing. Organizations should put resources into cutting edge programming instruments, like computer aided design, PLM (Item Lifecycle The executives), and reproduction stages, and guarantee that their labour force is sufficiently prepared to successfully utilize these apparatuses.

End

Model-Based Endeavor is a strong procedure that is changing assembling by empowering better cooperation, proficiency, and development. By taking on a computerized first methodology, organizations can further develop item quality, diminish costs, and speed up opportunity to showcase.

Model-Based Enterprise: Improving Collaboration Across the Supply Chain

https://www.marketdigits.com/model-based-enterprise-market

Model-Based Undertaking: Driving Effectiveness and Advancement in Assembling

The Model-Based Enterprise (MBE) is a ground breaking methodology in present day fabricating that use computerized models to improve item improvement, creation, and lifecycle the executives. By utilizing far reaching computerized portrayals, or models, all through the whole venture, MBE empowers further developed cooperation, smoothed out cycles, and information driven navigation.

What is Model-Based Enterprise?

A Model-Based Enterprise is an association where the legitimate wellspring of data for movements of every sort, from plan to assembling to quality confirmation, is a computerized model. This model, frequently made in PC supported plan (computer aided design) programming, contains itemized data about the item, including its calculation, materials, resistances, and execution determinations.

MBE is a characteristic movement from the Model-Based Definition (MBD) approach, which centres around inserting item and assembling information straightforwardly inside 3D models. MBE makes this a stride further by coordinating these models across the whole endeavour, guaranteeing that plan, assembling, quality, and different groups are working from a similar wellspring of data.

Key Advantages of a Model-Based Enterprise

Further developed Coordinated effort: In a Model-Based Enterprise, all partners access a solitary, shared computerized model that contains forward-thinking and exact data.

Improved Effectiveness: By supplanting paper-based processes with computerized work processes, MBE kills mistakes and adjust. For instance, fabricating groups can straightforwardly utilize the advanced model to program CNC machines or 3D printers, guaranteeing that the item is constructed definitively to the plan details. This diminishes the probability of creation blunders and abbreviates lead times, eventually prompting higher efficiency.

Better Quality Control: MBE considers more thorough quality control processes by empowering the mix of continuous information from assembling and review processes into the advanced model. This implies that any deviations from the plan particulars can be immediately recognized and amended, further developing item quality and diminishing waste.

Cost Reserve funds: The smoothed out processes and decreased blunders that accompany MBE bring about massive expense investment funds. Organizations can decrease material waste, limit adjust, and abbreviate creation cycles.

Support for Development: By using advanced models, MBE makes it more straightforward to try different things with new plans, materials, and creation techniques. Specialists can mimic various situations and advance plans for all intents and purposes prior to focusing on actual models, diminishing the time and cost related with item improvement.

Challenges in Taking on Model-Based Venture

Notwithstanding its various benefits, carrying out a Model-Based Enterprise accompanies difficulties. One of the most critical is the underlying interest in innovation and preparing. Organizations should put resources into cutting edge programming instruments, like computer aided design, PLM (Item Lifecycle The executives), and reproduction stages, and guarantee that their labour force is sufficiently prepared to successfully utilize these apparatuses.

End

Model-Based Endeavor is a strong procedure that is changing assembling by empowering better cooperation, proficiency, and development. By taking on a computerized first methodology, organizations can further develop item quality, diminish costs, and speed up opportunity to showcase.