High precision planetary reducers are essential components in the realm of industrial automation. They play a critical role in enhancing the efficiency and performance of various automated systems, from robotics to CNC machinery. This article delves into the significance of these reducers, their applications, advantages, and future trends in the industry.

Understanding Planetary Reducers

What Are Planetary Reducers?

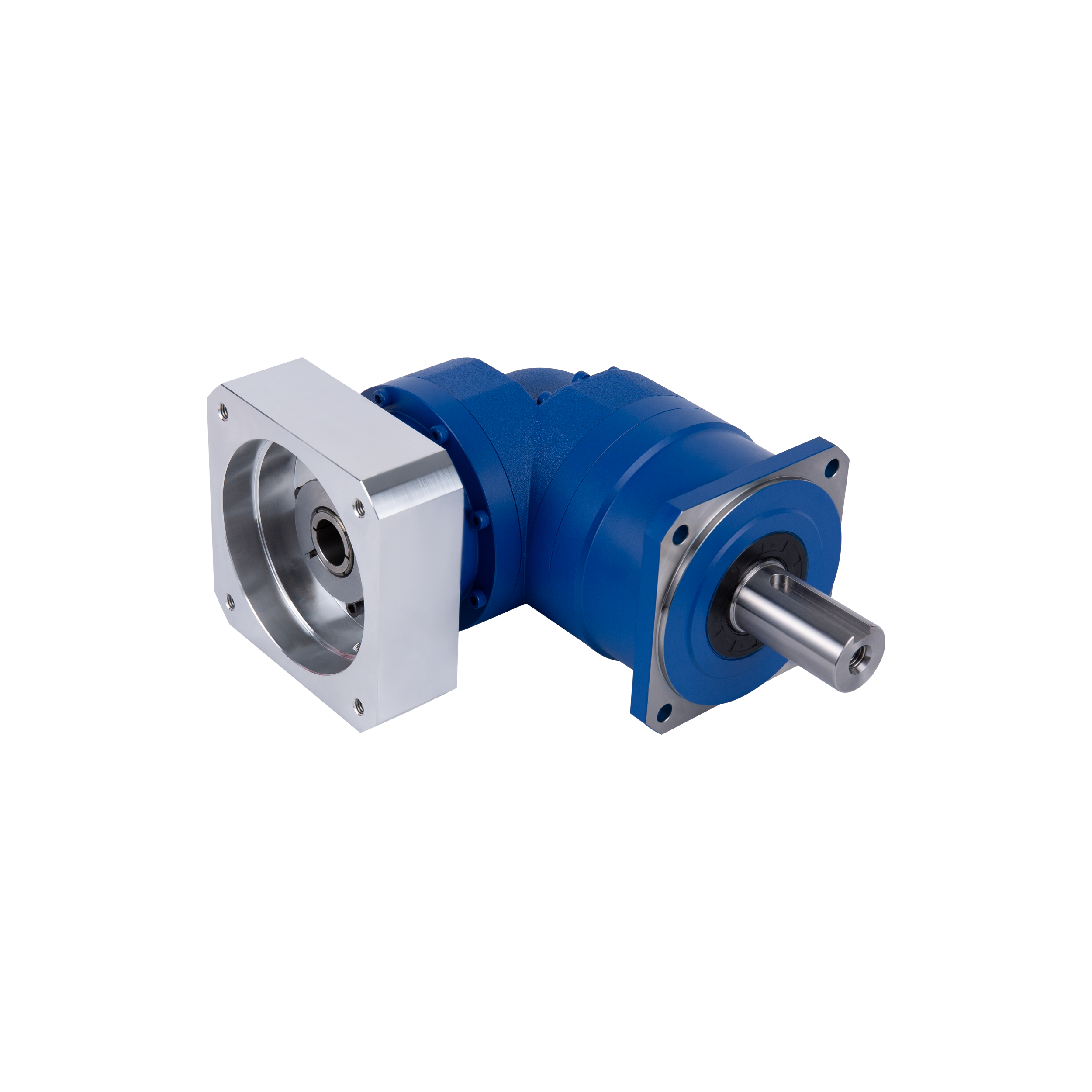

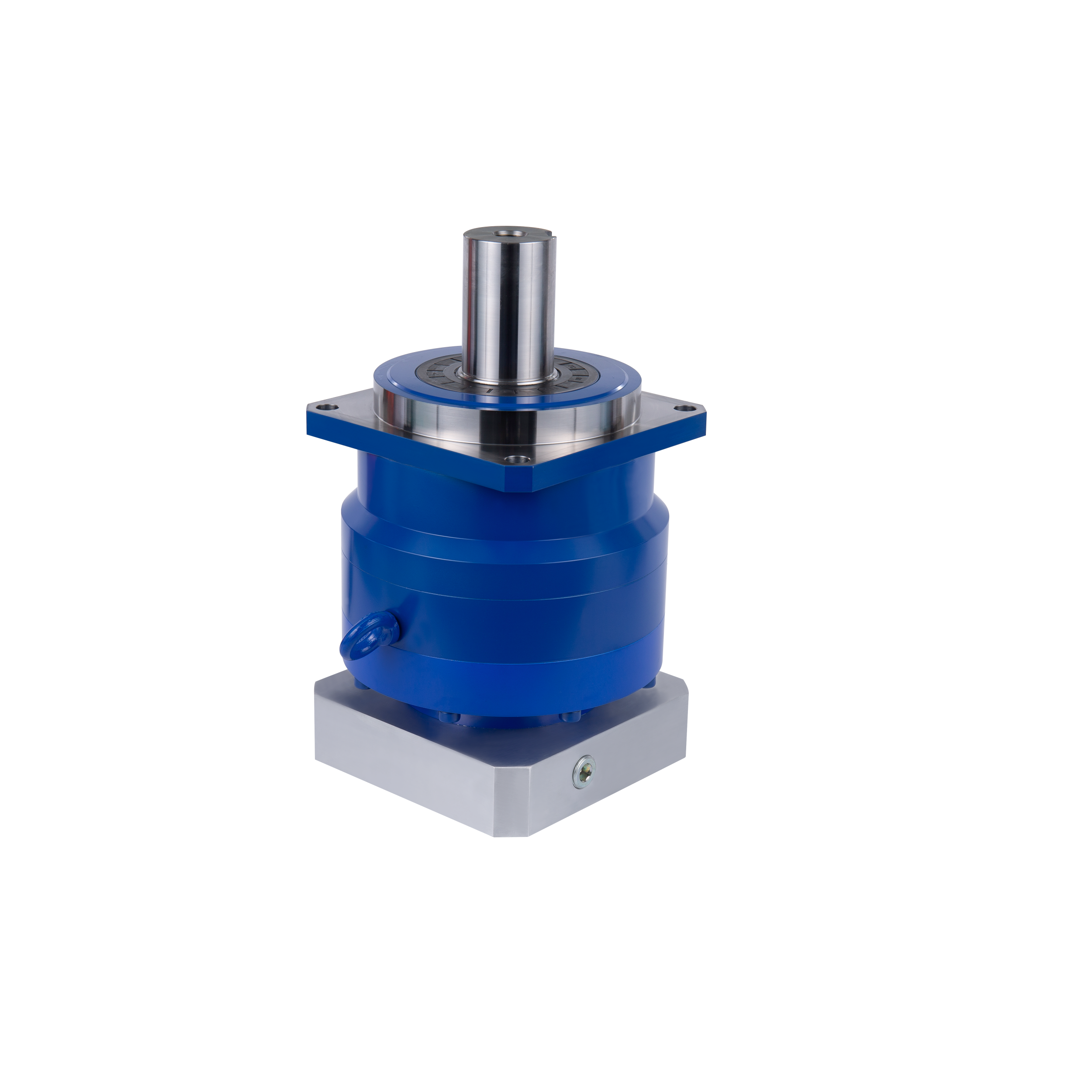

Planetary reducers, also known as planetary gearboxes, consist of three main components: the sun gear, planet gears, and the ring gear. This unique configuration allows for a compact design while providing high torque and low backlash. The planetary motion distributes load evenly across multiple gears, resulting in increased durability and efficiency compared to traditional gear systems.

How They Work

The operation of a planetary reducer involves the sun gear driving the planet gears that revolve around it while simultaneously engaging with the ring gear. This arrangement allows for significant speed reduction and torque multiplication, making them ideal for applications requiring precise motion control.

Applications in Industrial Automation

High precision planetary reducers are widely utilized across various sectors within industrial automation:

Robotics: In robotic systems, these reducers ensure accurate positioning and smooth motion control, essential for tasks such as assembly and material handling.

CNC Machinery: They enhance the performance of CNC machines by providing high torque at low speeds, which is crucial for machining operations that require precision.

Packaging Machinery: In packaging lines, planetary reducers facilitate fast and reliable operation, improving overall production efficiency.

Medical Equipment: Their reliability and precision make them suitable for medical devices that require exact movements, such as surgical robots and diagnostic machines.

Advantages of High Precision Planetary Reducers

1. High Efficiency

Planetary reducers boast high efficiency rates, often exceeding 95%. This is due to their design that minimizes energy loss through friction and heat generation.

2. Compact Size

The design of planetary reducers allows for a smaller footprint compared to other types of gear systems. This compactness is particularly advantageous in applications where space is limited.

3. Low Backlash

Backlash refers to the slight movement that occurs when the direction of rotation changes. High precision planetary reducers are designed to minimize backlash (often under 3 arc minutes), allowing for accurate positioning—an essential requirement in many automation applications.

4. Versatility

These reducers can be adapted to various motors and applications, making them versatile tools in the automation toolkit. They can be used in both linear and rotary motion systems across numerous industries.

Challenges in Implementation

While high precision planetary reducers offer numerous benefits, there are challenges associated with their implementation:

Cost: The initial investment for high-quality planetary reducers can be significant. However, their long-term benefits often justify this cost.

Complexity in Design: Designing systems that effectively integrate these reducers can be complex, requiring careful consideration of load requirements and operational conditions.

Future Trends

The future of high precision planetary reducers appears promising as industrial automation continues to evolve:

Integration with smart technology: With the development of industry, there is a growing trend to integrate smart technology with planetary reducers.This includes IoT capabilities that allow for real-time monitoring and predictive maintenance.

Sustainability Focus: There is an increasing emphasis on developing energy-efficient solutions within industrial automation. High precision planetary reducers are well-positioned to contribute to this trend by reducing energy consumption through efficient design.

Customization: Manufacturers are increasingly offering customized solutions tailored to specific industry needs, enhancing the applicability of planetary reducers across diverse sectors.

Conclusion

High precision planetary reducers play an indispensable role in advancing industrial automation. Their unique design offers numerous advantages such as high efficiency, compact size, low backlash, and versatility. As industries continue to innovate and adapt to new technologies, these reducers will remain at the forefront, driving improvements in performance and efficiency across a wide range of applications. With ongoing advancements in technology and a focus on customization and sustainability, the role of high precision planetary reducers is set to expand further in the future.

Exploring the Advantages of High Precision Planetary Reducers in Planetary Systems