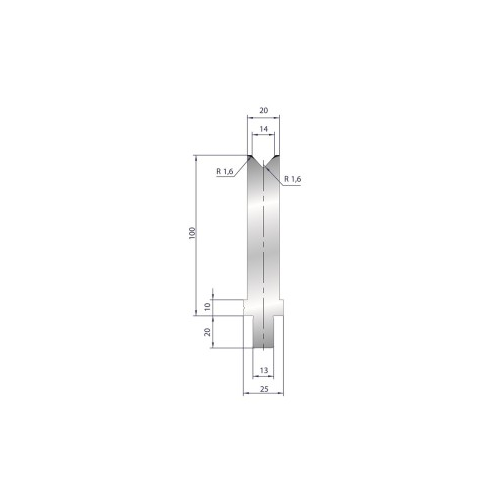

Maintaining the performance and longevity of your TRUMPF dies is crucial for ensuring consistent quality in your manufacturing processes. At AE Tooling, we provide high-quality dies, including the 3244 – 1V Dies – 84°, designed for durability and precision. This blog will outline essential tips and practices for properly maintaining and caring for your TRUMPF dies, helping you maximize their efficiency and lifespan.

1. Regular Cleaning

Keeping your TRUMPF dies clean is essential to prevent buildup of debris and contaminants that can affect performance. After each use, wipe down the dies with a soft cloth to remove any residue. For more thorough cleaning, use a suitable solvent that won’t damage the die material. Avoid abrasive materials that could scratch or wear down the surface.

2. Inspect for Wear and Damage

Regular inspections are vital to identify any signs of wear or damage early on. Check for nicks, scratches, or deformation on the die surfaces. If you notice any issues, address them promptly to avoid further damage or compromised performance. For example, the 3244 – 1V Die made from 42CrMo material is designed for durability, but regular checks will help maintain its integrity.

3. Proper Storage

When not in use, store your TRUMPF dies in a clean, dry environment to protect them from moisture and dust. Use protective cases or racks designed for die storage to prevent accidental damage. Ensure that the storage area is temperature-controlled to avoid extreme conditions that could affect the die material.

4. Lubrication

Applying the right lubricant can reduce friction and wear during operation. Use lubricants recommended by the manufacturer or those suitable for your specific die application. Regular lubrication helps maintain smooth operation and prolongs the life of your dies.

5. Follow Manufacturer Guidelines

Always refer to the manufacturer’s guidelines for specific maintenance recommendations related to your TRUMPF dies. These guidelines will provide insights into optimal operating conditions, cleaning procedures, and maintenance schedules tailored to your specific model.

6. Monitor Operating Conditions

Pay attention to the conditions under which your TRUMPF dies operate. Excessive heat, pressure, or improper alignment can lead to premature wear or failure. Ensure that your machinery is correctly calibrated and that operators are trained in proper die handling techniques.

7. Use Appropriate Materials

When using TRUMPF dies, ensure that you are processing materials that are compatible with their specifications. Using inappropriate materials can lead to increased wear or damage to the dies. For instance, ensure that the thickness and type of sheet metal align with the die’s design capabilities.

8. Document Maintenance Activities

Keep a detailed log of all maintenance activities performed on your TRUMPF dies, including cleaning schedules, inspections, repairs, and replacements. This documentation will help you track performance over time and identify any recurring issues that may need addressing.

Conclusion

Proper maintenance and care of your TRUMPF dies are essential for ensuring their longevity and optimal performance in manufacturing applications. By following these guidelines—regular cleaning, inspections, proper storage, lubrication, adherence to manufacturer guidelines, monitoring operating conditions, using appropriate materials, and documenting maintenance—you can maximize the efficiency of your dies like the 3244 – 1V Die from AE Tooling.

Investing time in maintaining your tools not only enhances productivity but also contributes to consistent product quality in your operations. If you have any questions about our products or need further assistance with maintenance practices, feel free to reach out!