In the manufacturing world, components like the Aluminum Roller play a significant role in ensuring smooth operation and product quality. The selection of these rollers affects both the efficiency and longevity of production machinery.

1. Why Material Matters in Roller Manufacturing

The choice of materials directly impacts roller performance. Aluminum is widely favored due to its lightweight nature combined with sufficient strength. The Aluminum Roller provides reduced mechanical strain on machinery, contributing to enhanced speed and reduced energy consumption. Additionally, aluminum resists corrosion better than many metals, which is critical for maintaining consistent operation in various environments.

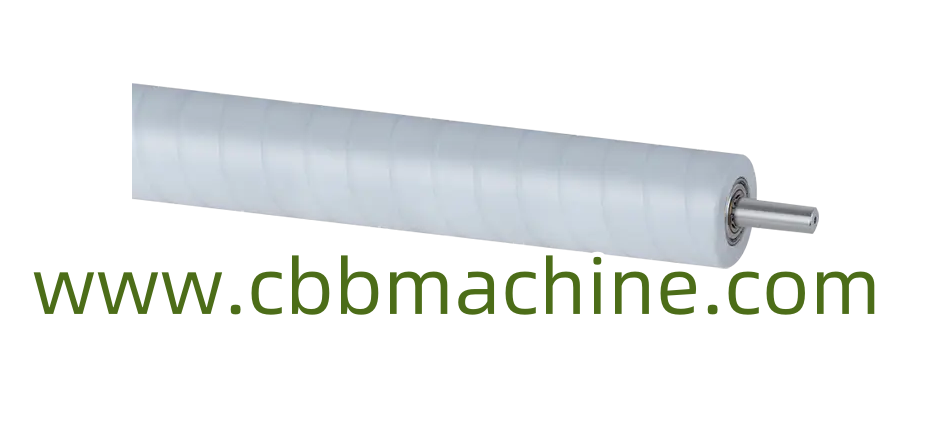

2. Features of CBB Machine’s Aluminum Rollers

CBB Machine is known for producing rollers that blend precision engineering with durability. Their rollers feature customizable specifications to meet diverse industry needs, including diameter, surface finish, and load capacity. This customization allows manufacturers to optimize rollers for specific tasks, improving workflow efficiency and reducing maintenance frequency.

3. Application Range Across Multiple Industries

Rollers are integral to numerous industries such as packaging, textiles, printing, and food processing. The precision and quality of rollers influence material handling, tension control, and alignment, which ultimately affect product consistency. By using high-quality rollers, companies can minimize product defects and machine downtime, improving overall productivity.

4. Maintenance and Care Guidelines for Aluminum Rollers

Proper maintenance is crucial for ensuring the long-term functionality of rollers. Regular inspections for wear, cleaning to remove debris, and proper lubrication help prevent damage. Aluminum rollers require particular attention to avoid surface scratches that may affect performance, but their corrosion resistance aids in preserving their surface integrity over time.

5. The Role of CBB Machine in Roller Innovation

CBB Machine continually advances roller manufacturing technology by integrating feedback from users and latest industry trends. Their focus on precision and customization allows them to cater to unique production challenges. Their commitment ensures clients receive rollers that not only meet but adapt to evolving operational requirements.

For more detailed information, please visit www.cbbmachine.com