Metal-Organic Framework

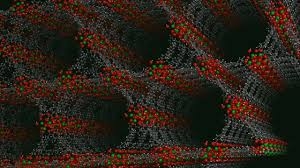

Metal-organic frameworks (MOFs) are a unique group of materials composed of metal ions or clusters attached by organic ligands into well-structured, porous frameworks. These atypical characteristics have drawn considerable interest in materials research due to their diverse pore sizes, exceptionally elevated surface areas, and multiple chemical functions. The design of metal-organic frameworks (MOFs) involves the coordination of metal nodes with organic linkers to establish a three-dimensional lattice that can be tailored for various applications.

Metal-organic frameworks possess many eminent advantages including very high space occupied by them which can go as high as 10000 m2/g MOFs are therefore suitable for gas separation and storage. For example they are used in energy storage and fuel cell technologies to store gases under high pressure such as hydrogen or methane. In addition, MOFs have shown promise in the crucial application of carbon dioxide capture and separation that reduce greenhouse gas emissions from power plants or industrial processes making it an important part of fighting climate change.

Furthermore, MOFs serve as flexible catalysts for various chemical processes due to their high surface area and possibility of changing pore environment [1]. As such they are preferred under catalytic conditions. Researchers have designed MOFs that act as catalysts during oxidation, fine compound synthesis or hydrocarbon conversion processes. Their effectiveness in these processes is improved by the ability to design them with specific active sites and functions[2].

Besides, it would be also possible to use MOFs for the purposes of water filtration and sensing. The large surface area that they possess together with their chemically adjustable characteristics make even minute quantities of pollutants or dangerous substances detectable in such a way as to show that this a possibility. In terms of water treatment, MOFs can clean and recycle water resources by adsorbing impurities such organic pollutants and heavy metals.

However, despite the promise they hold for many applications, Metal-organic frameworks still face some challenges namely stability, scalability and synthesis costs challenges. A lot is being done by scientists to increase the production of industrial MOFs, increase their robustness in different conditions as well as lower the cost of producing them.

In summary, Metal-Organic Frameworks are transformed materials that can be put into use in a number of ways, including drug delivery, pollution management, storing energy and sensing. This is because they have such exceptional high surface areas, tunable porosities and flexible chemistries making them suitable instruments to tackle a host of current scientific and industrial challenges. As research unfolds, it is projected that MOFs will gain more significance addressing numerous technical as well as ecological problems.