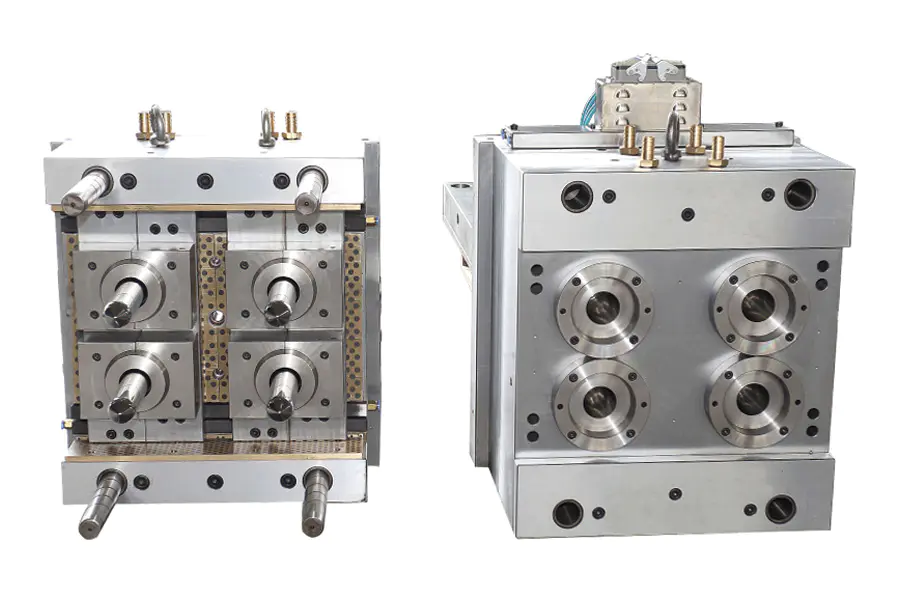

Sustainability managers now rank the 4 Cavity 3-Gallon Preform Mold as a cornerstone of any circular plastics strategy. Lightweighting algorithms built into the 4 Cavity 3-Gallon Preform Mold software trim gram weight by up to 4 % without sacrificing top-load strength, saving resin and freight emissions. An optimized cooling circuit within the 4 Cavity 3-Gallon Preform Mold halves water consumption versus legacy molds, helping plants meet ISO 14001 targets. Because every cavity in the 4 Cavity 3-Gallon Preform Mold is servo-balanced, energy draw remains steady, allowing factories to run on renewable power without spikes. Post-consumer rPET processes smoothly through the 4 Cavity 3-Gallon Preform Mold thanks to a vented screw and low-shear hot-runner nozzles that protect IV values. Life-cycle analysis confirms that bottles born from a 4 Cavity 3-Gallon Preform Mold generate 12 % less CO₂ from pellet to shelf than those from single-cavity tooling. Brands marketing eco-credentials can print a QR code on each bottle that links to the 4 Cavity 3-Gallon Preform Mold data log, proving recycled content and energy savings to conscious consumers.

البحث

الأقسام

- Politics

- الرئيسية

- Wellness

- Theater

- Sports

- Shopping

- Religion

- Party

- أخرى

- Networking

- Music

- Literature

- Art

- Health

- Gardening

- الألعاب

- Food

- Fitness

- Film

- Drinks

- Dance

- Crafts

- Causes

إقرأ المزيد

North America Panel Mount Industrial Display Market Analysis: Share Insights, Growth Scope, Current Movements, Future View, and Sector Breakdown

Executive Summary North America Panel Mount Industrial Display Market :

Data Bridge...

How does short message service (SMS) marketing work?

Executive Summary Short Message Service Market Size and Share Forecast

The global short message...

Hormone Havoc or Healing Ahead? Menopause Treatment Market Heats Up Amid Rising Demand

In a world where women’s health is finally getting the attention it deserves, one market is...

Ferrite Permanent Magnet Market - Strategic Developments

Business Market Insights recently announced the release of the market research titled Ferrite...

Sliding Centrifuge Market Size, Share - Industry Report, 2032

The Sliding Centrifuge Market is witnessing significant growth as industries across the globe...