Creating a reliable Plastic Cap Mold begins with meticulous design. Engineers first analyze the cap geometry, threading pitch, and tamper-evident band requirements. Every curve and undercut in the Plastic Cap Mold must be evaluated for material flow and cooling efficiency. Advanced CAD software simulates shear rates and pressure drops, ensuring the Plastic Cap Mold will fill evenly without weld lines. Once the 3D model passes virtual tests, CNC machines cut cavities and cores to micron-level accuracy, guaranteeing that each Plastic Cap Mold produces identical closures.

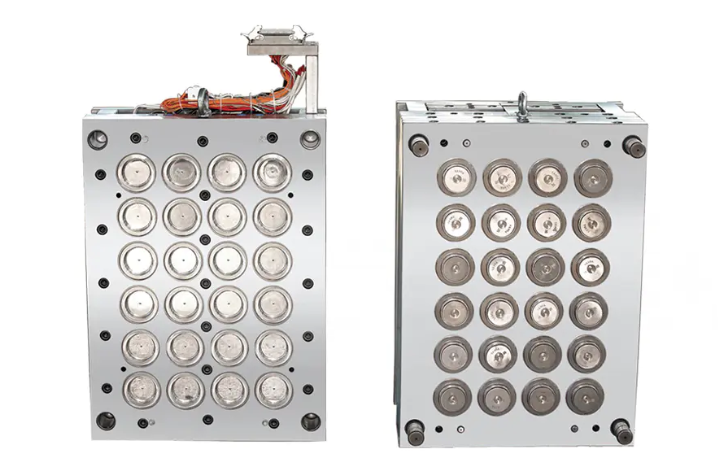

Material choice for the Plastic Cap Mold itself is equally vital. Hardened tool steels such as H13 or S136 resist abrasion from high-volume runs, while stainless options add corrosion resistance when molding aggressive resins. Designers incorporate interchangeable inserts within the Plastic Cap Mold so that future cap variants can be adopted quickly. Hot-runner systems keep the melt at a uniform temperature, reducing cycle time and waste. The Plastic Cap Mold is also fitted with precise temperature-control circuits; uniform cooling minimizes shrinkage and warping, ensuring that every cap threads smoothly onto bottles.

Finally, validation protocols confirm that the Plastic Cap Mold meets stringent quality standards. Pilot runs measure cap dimensions with laser scanners, while leak tests verify seal integrity under pressure. Any deviation triggers iterative tweaks to the Plastic Cap Mold until statistical process control charts show consistent capability. Once validated, the Plastic Cap Mold enters mass production, where robotic sprue pickers and in-mold closing systems keep cycle times under three seconds. Continuous monitoring of cavity pressure and temperature extends the Plastic Cap Mold life, delivering millions of flawless closures for beverage, pharmaceutical, and cosmetic brands worldwide.