Custom patches have long been a favorite solution for businesses, organizations, and individuals in the USA who want to create lasting impressions. Unlike printed logos or designs, patches provide texture, durability, and a professional finish that enhances apparel and accessories. From corporate uniforms and promotional items to fashion apparel and sports jerseys, patches communicate identity, quality, and style. They are more than decorative pieces—they are branding tools that leave a memorable mark.

The growing demand for high-quality custom patches reflects a shift towards products that combine aesthetics with longevity. Companies and individuals alike seek products that not only look professional but also last through repeated wear and washing. This is why patches are often complemented by specialized design processes such as vector art and embroidery digitizing, which ensure precision and flawless execution.

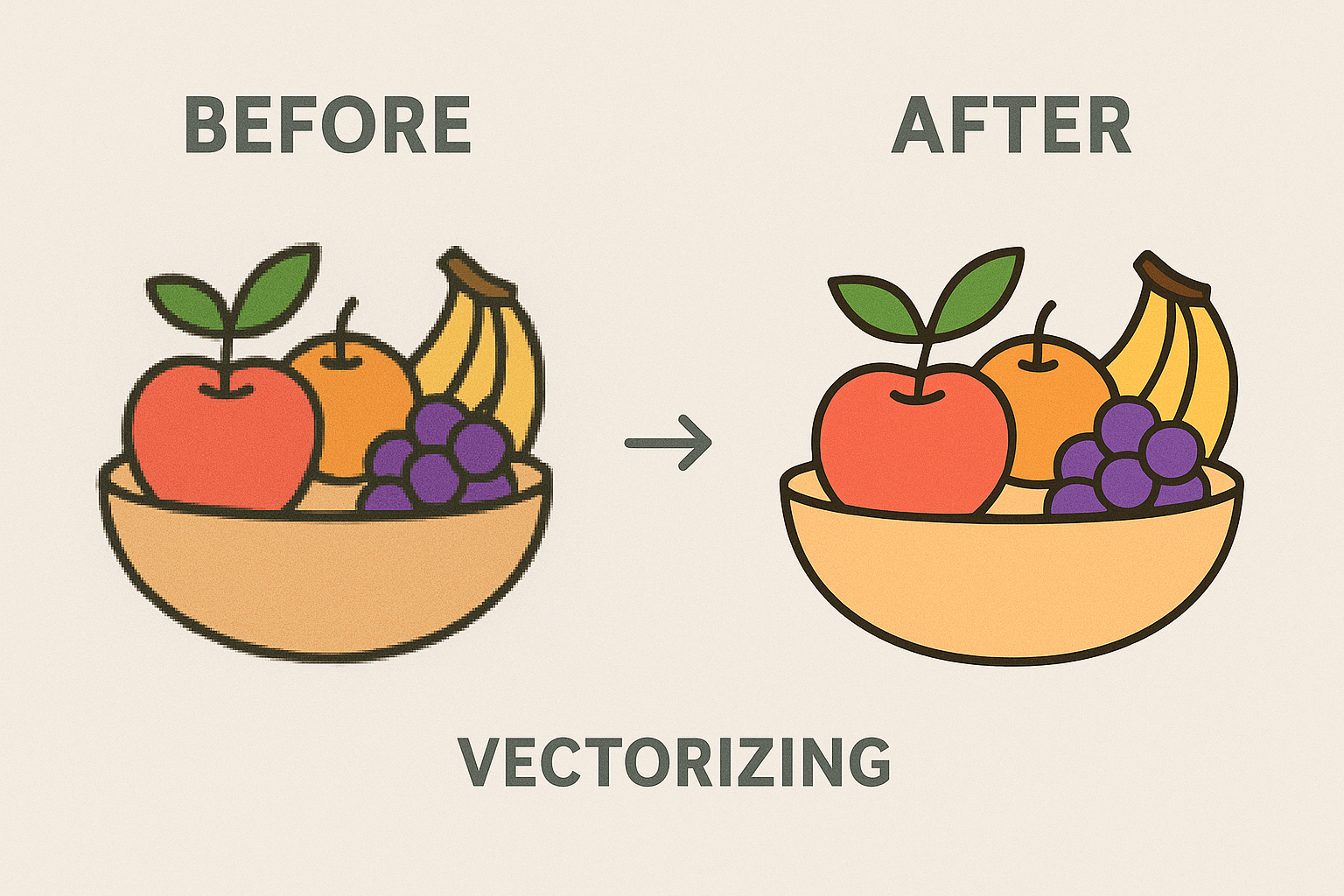

Vector Art: Building the Foundation for Quality Patches

A patch’s success starts with the artwork. Vector art is a crucial element in this process because it allows designs to be scaled without losing clarity. Unlike pixel-based images such as JPEGs or PNGs, vector graphics are built on mathematical paths and curves. This ensures that logos, emblems, or illustrations maintain sharp edges at any size, whether they are small hat logos or large jacket emblems.

For designers and businesses, vector art provides clean outlines, smooth curves, and precise shapes. These qualities make it easier for digitizers to translate the artwork into stitches accurately. The scalability of vector designs also allows patches to be applied to multiple types of products without compromising quality. For brands, this ensures consistent visual identity across uniforms, bags, caps, and promotional items.

Moreover, vector art simplifies adjustments during the design process. Colors, shapes, and text can be modified without losing detail, which makes revisions faster and more efficient. High-quality vector files are, therefore, indispensable for creating patches that look professional and polished.

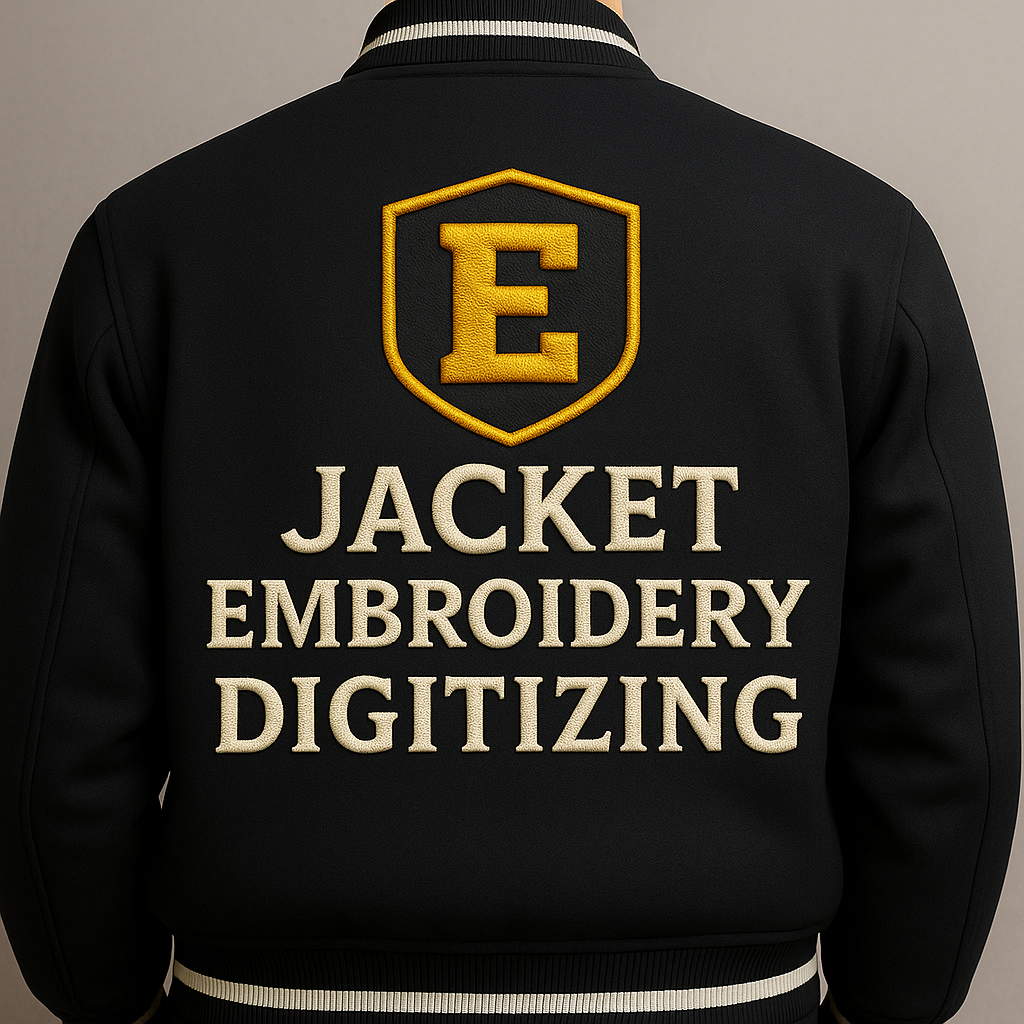

Embroidery Digitizing: Transforming Designs into Stitches

Once the vector file is ready, the next essential step is embroidery digitizing. This process converts the digital artwork into stitch files that embroidery machines can read and execute. Digitizing is both a technical and creative process. It requires understanding the type of fabric, stitch density, stitch type, and thread tension to produce a flawless embroidered design.

A professional digitizer determines which stitches—satin, fill, or running—are most suitable for the design and fabric. Stitch direction and density are adjusted to avoid puckering or distortion. Without proper digitizing, patches may have uneven edges, thread breaks, or inconsistent fills, leading to an unprofessional appearance.

Digitizing also plays a role in machine efficiency. Well-digitized files reduce machine downtime and waste by optimizing stitch paths. For businesses that order custom patches in bulk, this efficiency translates into faster turnaround times and lower production costs. Professional digitizing ensures that every patch meets quality standards and maintains consistency across multiple units.

Versatility and Functionality of Custom Patches

One of the most significant advantages of custom patches is their versatility. They can be sewn, ironed, or attached with Velcro, allowing them to be applied to a variety of surfaces. Businesses can place patches on uniforms, jackets, hats, and bags, while individuals can use them for personalizing apparel and accessories.

Patches also provide creative freedom. They can incorporate multiple colors, intricate designs, and unique shapes, offering endless possibilities for branding or personal expression. For sports teams, custom patches can display logos, achievements, or player numbers. For fashion brands, they can add distinctive details to jackets, backpacks, and hats.

Durability is another critical feature. High-quality patches made in the USA are designed to withstand repeated washing, heavy use, and exposure to elements without fading or losing shape. This long-lasting quality ensures that patches remain vibrant and professional over time, making them a cost-effective branding solution.

Custom Patches as a Branding Tool

For businesses, custom patches are more than decorative items—they are essential branding tools. Patches on uniforms, jackets, and promotional items increase brand visibility and reinforce identity. Unlike printed materials that can fade or peel, embroidered patches maintain their visual appeal for years.

Patches can also be used as collectible items or rewards. Organizations may create limited-edition patches to commemorate events, milestones, or achievements, enhancing employee or customer engagement. This not only strengthens loyalty but also creates a tangible connection between the brand and its audience.

Moreover, custom patches allow for flexible production. Businesses can create batches of patches separately and attach them as needed, saving time and reducing production costs. This approach is particularly useful for companies that require uniform patches for seasonal campaigns or varying product lines.

Fashion and Personal Expression

Beyond corporate and organizational uses, custom patches are increasingly popular in fashion. They allow individuals to express creativity and personal style on jackets, hats, backpacks, and other accessories. Fashion designers can experiment with textures, thread types, colors, and shapes to create visually striking patches that stand out.

Streetwear and independent fashion brands often leverage custom patches to add a unique touch to their collections. Patches can transform a plain garment into a statement piece, providing versatility and customization options that appeal to modern consumers.

Professional Expertise Ensures Quality

Creating high-quality custom patches requires expertise. Experienced professionals understand the nuances of stitching, thread tension, fabric behavior, and design adaptation. By combining vector art with embroidery digitizing, they ensure that designs are faithfully reproduced in patch form.

Professional services deliver consistent, durable, and visually appealing patches that meet brand standards. This expertise reduces errors, minimizes waste, and ensures a faster production timeline. Businesses benefit from reliable products that uphold their professional image while leaving a lasting impression on clients and customers.

Conclusion: Quality Custom Patches for Lasting Impact

Custom patches are an effective way to elevate brand identity, express personal style, and create durable, eye-catching designs. With the support of precise vector art and expert embroidery digitizing, these patches achieve professional-quality results that stand the test of time.

Whether for corporate uniforms, sports apparel, promotional items, or fashion pieces, investing in high-quality USA-made patches ensures designs are visually striking, long-lasting, and consistent. By leveraging the expertise of professionals and the precision of modern techniques, businesses and individuals can transform their logos and artwork into embroidered patches that make a lasting impression.