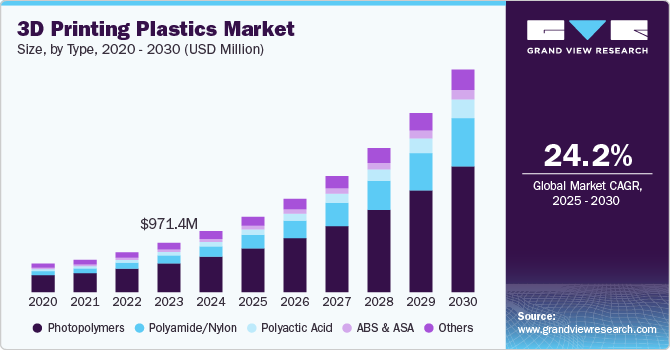

The global 3D printing plastics market was valued at approximately USD 1.20 billion in 2024 and is anticipated to grow at a remarkable compound annual growth rate (CAGR) of 24.2% from 2025 to 2030. This growth is primarily driven by the increasing demand for customized and personalized products, which is fostering innovation within the 3D printing sector and subsequently heightening the need for various types of 3D printing plastics.

A significant trend observed in the market is the strong shift toward sustainable and eco-friendly materials. As industries adopt more responsible manufacturing practices, there is a notable rise in the popularity of bioplastics and recycled materials for use in 3D printing applications. This movement is propelled by stringent environmental regulations and an increasing consumer preference for sustainable products. Companies are actively investing in research and development to create innovative biodegradable plastics that can match the performance characteristics of traditional materials while minimizing environmental impact. This transition not only supports sustainability objectives but also opens new avenues for growth in sectors such as healthcare and consumer goods.

Gather more insights about the market drivers, restrains and growth of the 3d Printing Plastics Market

Type Insights

When examining the market by type, the photopolymers segment emerged as the leader, accounting for a substantial revenue share of 58.4% in 2024. This dominance can be attributed to the rising demand for high-precision manufacturing across various industries, including dental, jewelry, and electronics. Photopolymer resins, which solidify when exposed to light, are prized for their exceptional accuracy and ability to produce intricate details, making them particularly suitable for creating complex designs.

In the dental sector, for example, photopolymer 3D printing technology is utilized to manufacture highly customized crowns, bridges, and dental implants with remarkable precision. Similarly, in the electronics industry, this technology is applied to create micro-scale components that would be challenging to fabricate using traditional manufacturing methods. The growing inclination toward customized and miniaturized products, along with advancements in photopolymer formulations that enhance strength and durability, is propelling the growth of this market segment.

On the other hand, the polyamide/nylon segment is projected to experience rapid growth throughout the forecast period. Nylon is well-regarded for its outstanding mechanical properties, including high tensile strength, flexibility, and durability. These attributes make it particularly suitable for producing functional prototypes and end-use parts across various industries, including automotive, aerospace, and consumer goods. In the automotive and aerospace sectors, manufacturers are increasingly adopting Nylon 3D printing to create lightweight components that help reduce the overall weight of vehicles without compromising performance. This shift is further reinforced by the material's resistance to heat and chemicals, which is essential for applications in demanding environments.

Global 3D printing plastics market is on an upward trajectory, driven by the need for customization and sustainability. As companies continue to innovate and adapt to market demands, particularly through the use of photopolymers and polyamides, the industry is well-positioned for significant growth in the coming years. This evolving landscape reflects broader trends in manufacturing and consumer preferences, emphasizing the importance of both performance and environmental responsibility in product development.

Order a free sample PDF of the 3d Printing Plastics Market Intelligence Study, published by Grand View Research.